MHEC is employed being a rheology modifier and thickener in paint and coatings formulations. It enhances the viscosity, security, and move features of the paint, making certain appropriate software and coating performance.

Improved Adhesion: MHEC powder functions being a thickening and bonding agent, marketing much better adhesion of products to varied surfaces. This can be crucial in purposes like tile adhesives, wherever sturdy and extended-Long lasting bonds are expected.

Methyl hydroxyethyl cellulose (MHEC) can be utilized as an additive in cement slurry in properly therapy to forestall or reduce the incidence of gas channeling. Besides acting for a gas Handle additive, methyl hydroxyethyl cellulose controls fluid decline, minimizes free of charge fluid and stabilizes foam all through cementing.

The following action encompasses etherification via sodium mono chloroacetate, culminating within the production of MHEC. This resultant material is then subjected to purification, drying, and milling, in the long run yielding the ultimate MHEC product.

The gelation temperature of MHEC is additionally bigger than that of MC. MHEC is a common non-ionic h2o-soluble cellulose ether. It might improve the regularity and water retention of water-primarily based products.

Compatibility: MHEC is compatible with an array of other ingredients and additives, which makes it versatile and simple to include into various formulations devoid of creating undesirable interactions or compromises in general performance.

Constructing Grade MHEC performs a vital role in dispersion and emulsification procedures through the production of construction supplies. By aiding during the uniform distribution of particles and facilitating the formation of secure emulsions, MHEC ensures homogeneity in the end products.

On top of that, the impact of various viscosity quality around the thickening residence can alsobe clearly viewed, below the opposite continuous parameters, the viscosity of HEMC cellulose boosts with the increase of viscosity grade.

This property is useful in applications exactly where publicity to large temperatures is expected, such as in construction elements or industrial procedures.

4. Methyl cellulose has a visible impact on the workability and adhesion of mortar. "Adhesion" refers back to the adhesion power concerning the employee's application Resource and also the wall substrate, i.e., the shear resistance of your mortar. A better adhesion leads to increased shear check here resistance, requiring additional force with the worker for the duration of software and resulting in poorer workability. Between cellulose ether products, methyl cellulose features a average degree of adhesion. HPMC means Hydroxypropyl Methyl Cellulose. It's a non-ionic cellulose ether derived from refined cotton by alkalization, making use of epichlorohydrin and chloromethane as etherification brokers in a very series of reactions. The diploma of substitution is mostly concerning one.two and a pair of.0. Its Homes change Along with the ratio of methoxy information to hydroxypropyl material. (1) Hydroxypropyl Methyl Cellulose is soluble in chilly drinking water, but it may be difficult to dissolve in incredibly hot drinking water. Nevertheless, its gelation temperature in hot h2o is drastically greater than that of methyl cellulose. Its solubility in chilly water is significantly improved as compared to methyl cellulose. (two) The viscosity of Hydroxypropyl Methyl Cellulose is determined by its molecular weight, with higher molecular bodyweight bringing about greater viscosity. Temperature also affects its viscosity, with viscosity decreasing as temperature rises.

These properties make HEMC broadly Employed in cement mortars, gypsum products, and tile adhesives in the construction industry.

On the other hand, its viscosity is much less affected by temperature in comparison to methyl cellulose. Its Answer is stable when saved at home temperature. (three) Hydroxypropyl Methyl Cellulose displays steadiness in acids and alkalis, and its aqueous Option is very steady within the pH selection of 2 to 12. It can be minimally influenced by sodium hydroxide and lime drinking water, Despite the fact that alkalis can speed up its dissolution and marginally enhance its viscosity. It demonstrates steadiness generally speaking salts, but at increased salt concentrations, the viscosity of Hydroxypropyl Methyl Cellulose solution tends to raise. (4) The drinking water retention potential of Hydroxypropyl Methyl Cellulose depends on aspects like the dosage and viscosity, and at precisely the same dosage, its h2o retention rate is higher than that of methyl cellulose. (five) Hydroxypropyl MHEC for the construction industry Methyl Cellulose could be blended with drinking water-soluble large molecular fat compounds to sort homogeneous remedies with bigger viscosity. Examples incorporate polyvinyl alcohol, starch ethers, and plant gums. (six) Hydroxypropyl Methyl Cellulose reveals larger adhesion in mortar construction compared to methyl cellulose. (seven) Hydroxypropyl Methyl Cellulose has far better resistance to enzymatic degradation compared to methyl cellulose, and its Alternative is more unlikely to bear enzymatic degradation.

Adhesion: Boosts the bonding strength on the plaster for the substrate, making sure superior adhesion and durability.

MHEC-based hydrogels have discovered programs in wound dressings, drug delivery devices, and tissue engineering due to their biocompatibility and tunable related read Attributes.

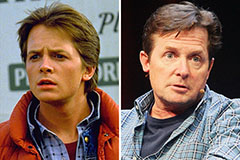

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!